- +86 136 65744767

- 09:00 AM - 5:00 PM

In today’s waste-conscious world, effective recycling and waste management practices are crucial for both environmental sustainability and operational efficiency. One often-overlooked but critical component in this process is the baling strap—also known as baler tape, baling tape, baler strapping, or baler string. While it may seem like a small detail, selecting the right type of baling strap can make a significant difference in safety, cost-effectiveness, and overall performance.

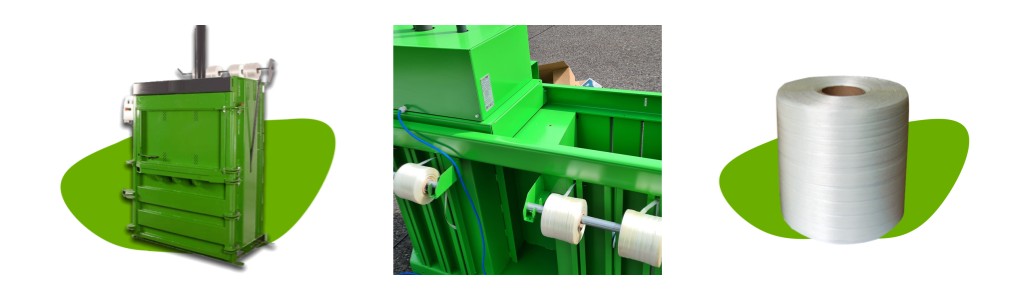

Baling strap is used to tie compressed bales of recyclable materials such as cardboard, plastics, and textiles. These straps keep materials securely bound during storage and transport, preventing spills, maintaining bale integrity, and ensuring efficient handling throughout the recycling process. For recycling centers, logistics companies, and industrial facilities, the choice of baling strap is not just about convenience—it's about reliability and risk reduction.

There are different types of baling strap on the market, including polypropylene twine, polyester strapping, and composite or fiber-based straps. Each variety comes with specific strength ratings and elongation properties. The right choice depends on the type of material being baled, the compression force of the baling machine, and the storage or shipping conditions.

For instance, lighter materials such as shrink wrap or film may only require low-tension baler string, while dense, high-pressure cardboard bales demand high-tensile composite straps. Using understrength strapping can result in dangerous breakages and scattered waste, which not only poses a safety hazard but also increases labor and reprocessing costs. On the other hand, over-specifying the strap can lead to unnecessary expenses.

Industry experts recommend considering both the break strength and elongation rate when selecting a baling strap. A good baling strap should offer a balance of tensile strength and flexibility—strong enough to hold the bale, but with enough stretch to accommodate shifts during transportation or handling.

Moreover, environmental factors are increasingly shaping buyer preferences. As sustainability becomes a higher priority, many companies are turning to recyclable and eco-friendly strapping options. Some manufacturers now offer biodegradable baler tape or straps made from post-consumer recycled materials, aligning waste management practices with broader corporate social responsibility goals.

Another important aspect is compatibility with baling equipment. Certain straps are designed to work seamlessly with automatic or semi-automatic balers, allowing for faster processing times and reduced manual labor. Ensuring that your strap fits the specifications of your machinery can significantly improve efficiency on the recycling line.

Finally, suppliers play a vital role in ensuring product reliability. Trusted manufacturers and distributors will not only provide consistent strap quality but also offer technical support to help you choose the correct type of strap for your unique operation.

In conclusion, choosing the right baling strap may seem like a minor logistical detail, but it has a major impact on safety, cost, and sustainability. By carefully evaluating material strength, baler compatibility, environmental considerations, and supplier reliability, businesses can make informed decisions that enhance the effectiveness of their recycling efforts.

As the global demand for efficient and sustainable waste management grows, making smart choices in every aspect of the process—including baling strap selection—is more important than ever.