- +86 136 65744767

- 09:00 AM - 5:00 PM

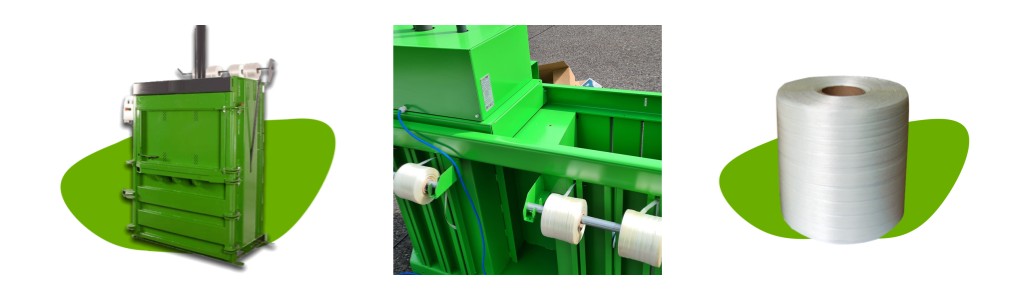

In industries where bales are tightly compacted, such as agriculture, recycling, and waste management, securing the load effectively is crucial. Heavy bales, made from materials like cardboard, plastic, or hay, require a reliable method of containment during storage, transportation, and compression. That's where baling strapping shines—offering exceptional shock absorption, it is the ideal solution for securing even the heaviest and most densely packed bales with ease.

Baling strapping, also known as banding or binding, is used to hold compacted bales together to prevent them from falling apart or shifting during transit. It is made from various materials, such as polyester, polypropylene, or composite fibers. What sets modern baling strapping apart is its enhanced shock-absorbing properties. The strength and elasticity of these materials allow them to absorb the energy from external impacts, making it easier to handle bulky, dense, or irregularly shaped bales.

Unlike traditional methods such as wire or twine, which can snap under stress or lose tension over time, high-quality baling strapping provides lasting durability, ensuring bales stay intact even under harsh conditions. Whether transporting hay bales across a farm or moving plastic bundles in a recycling facility, baling strapping ensures that your load remains secure, even when faced with rough handling or sudden impacts.

Agriculture

In the agricultural sector, baling strapping is essential for tying hay, straw, or silage bales that are often heavy and prone to shifting. The strap’s shock-absorbing qualities help it retain tension even when bales are subjected to sudden movement or weight changes. With consistent tension and strength, baling strapping keeps the bales intact, preventing loss and waste.

Recycling

The recycling industry is known for processing various materials, often under challenging conditions. Baling strapping is used extensively to bind large quantities of recyclable materials, such as cardboard, plastics, and metals. The shock-absorbing nature of the strapping ensures that even heavy, tightly packed loads remain secure during storage and transportation. This reduces the risk of accidents or disruptions in the supply chain, contributing to safer and more efficient recycling operations.

Waste Management

Waste management facilities regularly deal with dense bales of compacted paper, plastics, or other materials. The shock-absorbing properties of baling strapping help ensure that these bales do not break apart during handling or transport. It also makes the bales easier to stack and store without the risk of them toppling or shifting, improving both safety and efficiency in waste processing.

Enhanced Durability

Shock-absorbing baling strapping is engineered to resist the stresses of heavy loads and impacts. Its elasticity allows it to stretch slightly and absorb shocks without breaking or losing strength. This increased durability extends the life of the strap, reducing the need for frequent replacements and maintenance.

Improved Load Security

Heavy or irregularly shaped bales are more susceptible to shifting during transit or storage. Shock-absorbing strapping ensures that bales remain securely bound, even in conditions where traditional methods might fail. The strap’s flexibility allows it to conform to the shape of the bale, providing better grip and preventing any risk of breakage or displacement.

Ease of Handling

Unlike steel straps, which can be difficult and dangerous to handle, baling strapping is lightweight and easier to work with. The shock-absorbing feature adds an extra layer of safety, making it simpler to apply the strap without worrying about sharp edges or accidental injury. This is particularly important in environments where workers must handle large volumes of bales daily.

Cost-Effectiveness

The ability of shock-absorbing baling strapping to withstand harsh conditions translates into long-term cost savings. Its enhanced durability reduces the frequency of replacements, while its ability to secure heavy loads means fewer instances of lost or damaged goods. This makes it a cost-effective solution for industries that require reliable, long-lasting strapping options.

Sustainability

As industries continue to focus on sustainability, baling strapping made from recyclable or eco-friendly materials contributes to reducing the environmental impact. By choosing high-quality, reusable strapping, businesses can lower their carbon footprint while maintaining operational efficiency.

Baling strapping with exceptional shock absorption is revolutionizing the way industries secure and handle heavy, compacted loads. Its durability, flexibility, and ability to absorb external impacts make it the ideal solution for agricultural, recycling, and waste management applications. Whether for heavy hay bales or tightly packed recyclable materials, shock-absorbing baling strapping ensures that the load stays secure, reducing waste, enhancing safety, and ultimately improving operational efficiency.