- +86 136 65744767

- 09:00 AM - 5:00 PM

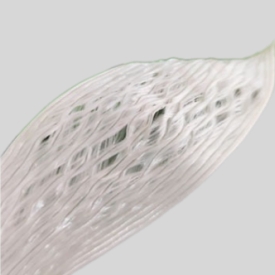

In the bustling world of agriculture and waste management, efficiency and sustainability are paramount. Among the myriad tools and technologies that keep these industries running smoothly, baling straps have emerged as an indispensable asset. These robust bands, often made from materials like polyester or steel, are primarily used to secure waste materials onto pallets, ensuring safe and efficient transportation. Their widespread adoption across these sectors underscores their importance in modern industrial operations.

**The Role of Baling Straps in Agriculture**

In the agricultural sector, baling straps are commonly used to bundle hay, straw, and other crops. Farmers rely on these straps to create compact, manageable bales that can be easily transported and stored. The durability of baling straps ensures that the bales remain intact, even under harsh weather conditions. This not only preserves the quality of the crops but also minimizes waste, a critical consideration in an industry where margins can be thin.

Moreover, the use of baling straps in agriculture contributes to sustainability efforts. By enabling efficient storage and transportation, these straps help reduce the carbon footprint associated with agricultural logistics. Farmers can transport larger quantities of crops in fewer trips, leading to lower fuel consumption and reduced greenhouse gas emissions.

**Baling Straps in Waste Management**

The waste management industry has also embraced baling straps as a vital tool for handling and transporting recyclable materials. Waste materials such as cardboard, paper, and plastics are often compressed into bales using heavy machinery. Baling straps are then used to secure these bales onto pallets, ensuring they remain stable during transit.

This method of banding waste to pallets offers several advantages. Firstly, it maximizes the use of available space, allowing more waste to be transported in a single load. This efficiency translates to cost savings for waste management companies and, ultimately, for consumers. Secondly, securely banded bales are less likely to shift or spill during transportation, reducing the risk of accidents and environmental contamination.

**Innovations in Baling Strap Technology**

As industries continue to evolve, so too does the technology behind baling straps. Manufacturers are now producing straps with enhanced tensile strength and resistance to environmental factors such as UV radiation and moisture. These advancements ensure that baling straps can withstand the rigors of heavy-duty use, further extending their lifespan and reliability.

Additionally, there is a growing focus on the environmental impact of baling straps themselves. Many companies are exploring the use of recyclable materials in strap production, aligning with broader sustainability goals. Some manufacturers are even developing biodegradable straps, which could significantly reduce the environmental footprint of waste management operations.

**Conclusion**

Baling straps may not be the most glamorous tools in the agricultural and waste management industries, but their impact is undeniable. By providing a reliable and efficient method for bundling and transporting materials, these straps play a crucial role in maintaining the smooth operation of these sectors. As technology continues to advance, we can expect baling straps to become even more integral to industrial processes, driving further efficiencies and sustainability gains.

In a world where every ounce of efficiency counts, baling straps are proving to be a small but mighty force, helping industries meet the challenges of today and tomorrow.